Scale Parts Washer

2024-02-02 18:09:31

The machine could be operated for the requirements of one rack of scale parts cleaning and one rack drying at the same time;

The loading and unloading process separately operated on two sides of the machine body, require two persons;

The cleaning and drying time is synchronized, needs 8~10 min./rack.

Cleaning steps:

Plan A

1. Manually loading parts rack to the washing room;

2. Manually close the front door;

3. Spray washing;

4. Spray rinsing;

5. Compressed air blowing the inside water;

6. The middle automatic door shifts opened

Rack automatically enters the drying and sterilization room, while at the same time, rack is manually put into the washing room.

Plan B

Similar to Plan A, but with below difference:

Only one rack of scale parts goes into cleaning and drying room at the same time;

I.e.:

After drying, the rack goes back to loading position for unloading. Only needs one person but double time operation for each rack.

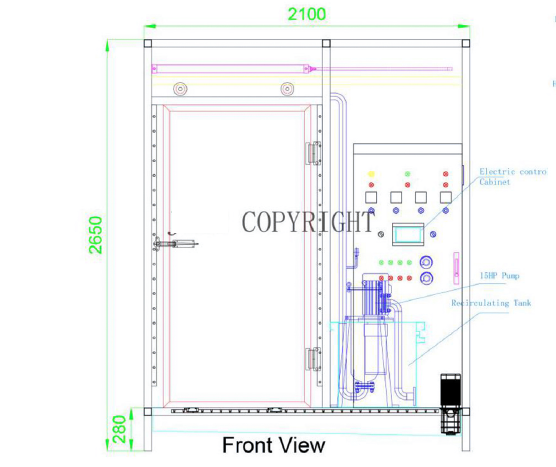

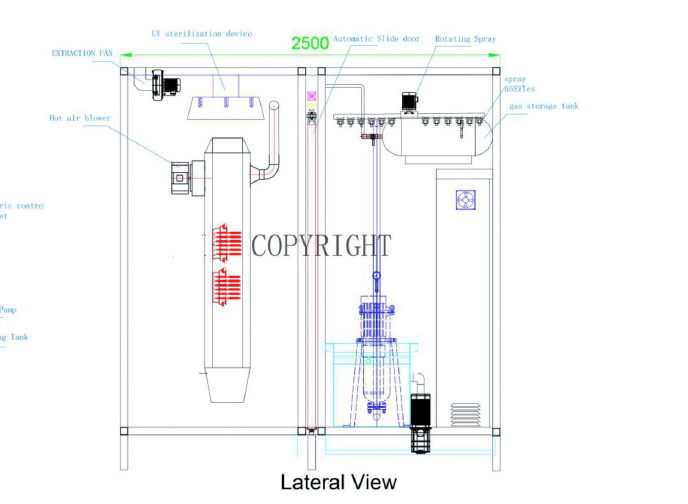

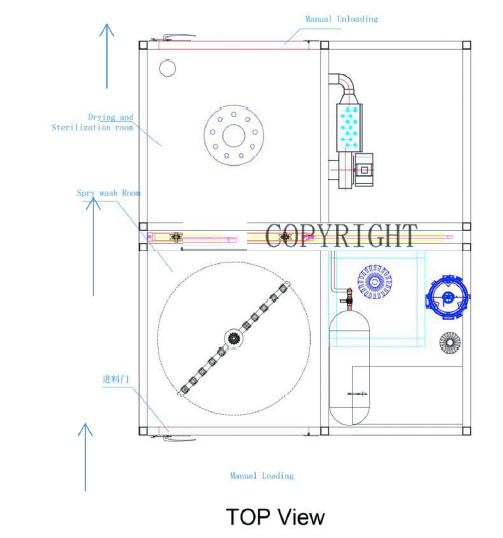

Machine draft drawing:

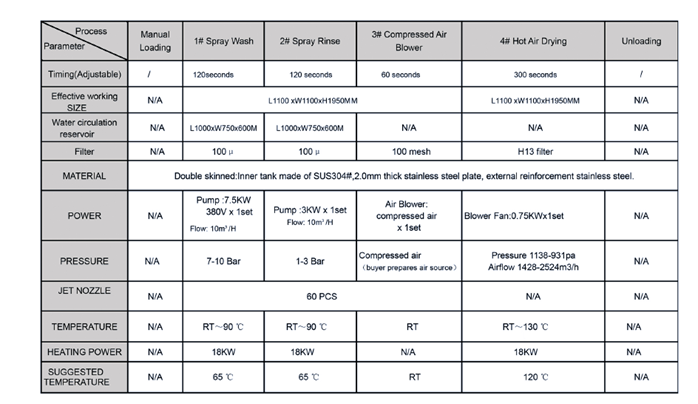

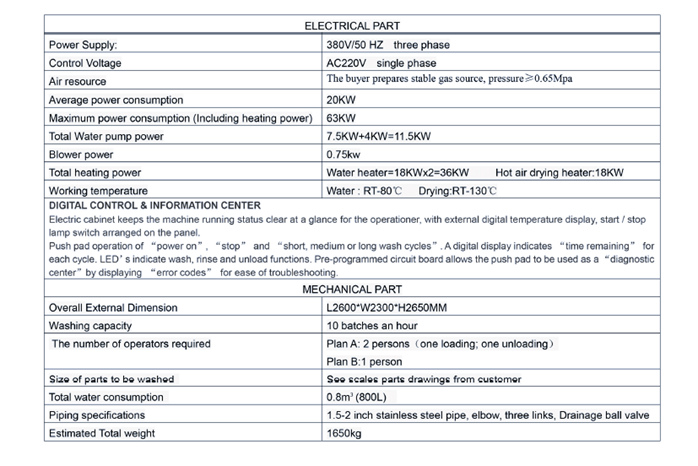

Basic datasheet: